Bio-based materials

Advancing renewable feedstocks

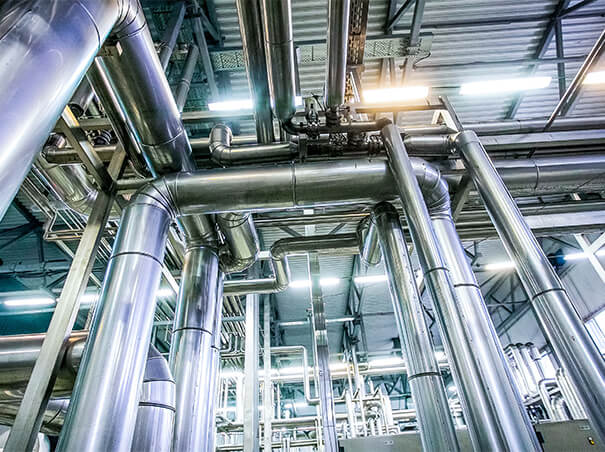

Though feedstocks are typically derived from fossil fuels, they don’t have to be. Our pioneering work in developing ECOLIBRIUM™ Technology allows us to transform bio-based, sustainably sourced waste and by-products from other industries into feedstocks with a lower carbon impact.

Advanced recycling

Ensuring feedstocks have a circular future

To create a truly circular polymer, the world needed a way of turning used plastics back into high-quality feedstock to make virgin-like plastic. And in collaboration with advanced recycling technology companies, we’ve developed such a process. Using it, we’re capable of turning plastic waste into feedstocks that can create new, durable, food-grade polymers that are resource efficient—and ultimately drive sustainable circularity by giving value to what once was considered waste.

Mass balance

Meeting the demand for better

Businesses and consumers alike want change. And to meet that, we’ve dramatically increased the number of sustainable feedstocks going into our production lines. By mass balancing this way (rather than creating dedicated lines for producing bio-based or circular polymers), we’re lowering the environmental impact of our process and ensuring the world gets sustainable polymers in the most cost-efficient way.

We partnered with Chemical Kim, scientist and TikToker, to ask - what is the future of recycling?

Watch as she explains how plastics recycling is changing and how we can give plastics a new life,

again and again.

Growing access to sustainable feedstocks

We continue to pursue allies for developing and commercializing bio-based and plastic waste feedstocks across the world. Take a look at the work we are doing together.